Nitrite is a corrosio inhibitor present in heavy-duty antifreeze, primarily used for the prevention of cavitation wet sleeve liner pitting. Cavitation is a type of corrosion that occurs in heavy-duty engines when bubbles continuously form and burst on the “wet” side of a wet sleeve liner. Without proper inhibitors, typically nitrite and/or molybdate, to form a protective barrier, wet sleeve liners in heavy-duty applications are unprotected and can develop catastrophic damage! One of the primary issues with nitrite is that is heat-sensitive and depletes over time. This is why with conventional technology coolants that primarily use nitrite to protect against liner pitting, the SCAs must be tested and maintained throughout the life of the coolant.

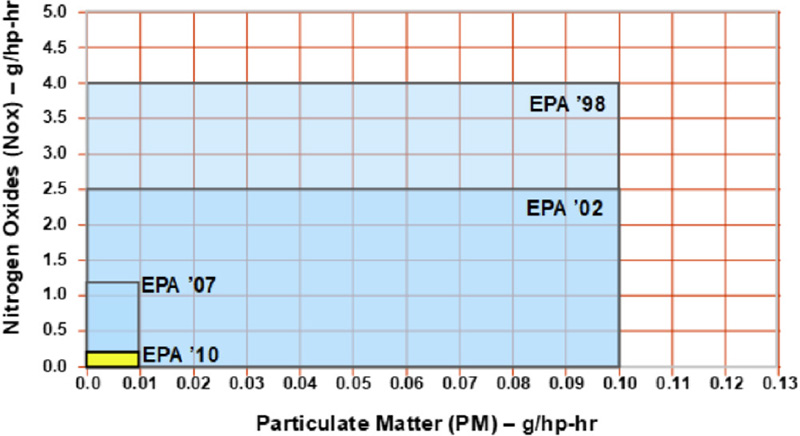

The birth of nitrite-free coolant began with the introduction of emissions requirements for heavy-duty on-the-road vehicles. Beginning in 1985, the EU and the EPA started tiered regulations for diesel exhaust emissions. With each successive tier of regulations, the permitted levels of nitrogen oxides (NOx) and particulate matter (PM), the two primary pollutants from diesel engines, have gone down significantly (see chart below).

To meet increasingly stringent EPA requirements, heavy-duty OEMs developed emissions reduction innovations such as diesel exhaust filters and exhaust gas recirculation (EGR) systems, both of which increase the amount of heat that the coolant must absorb. The EGR system alone increases the coolant’s heat intake by 25-30%!

As a result of the additional cooling needs of modern diesels, the heat-sensitive nitrite in heavy-duty coolant was being used up more quickly, the coolant requiring even more frequent maintenance. This spurred the production of nitrite-free antifreeze/coolant, which uses a more temperature-stable corrosion inhibitor, like molybdate, in place of nitrite.

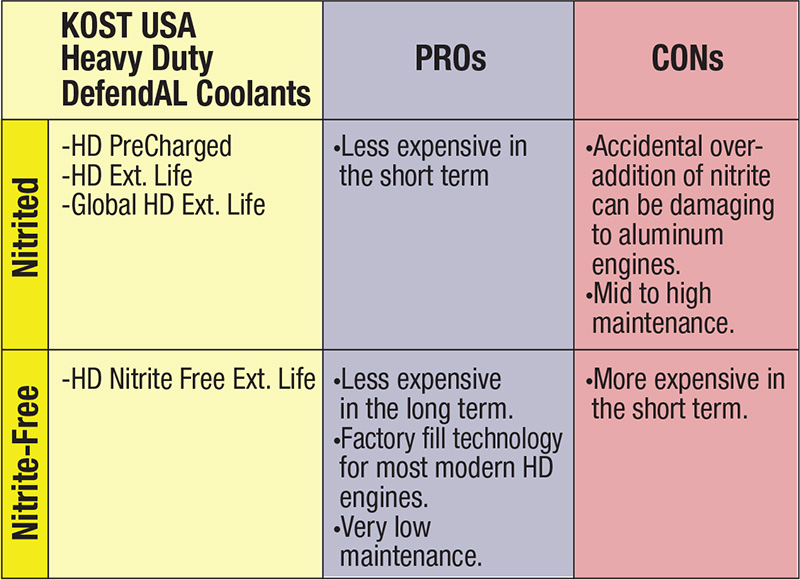

The above chart will assist you in choosing the correct antifreeze. Always keep in mind your application, budget, and how rigorous a maintenance schedule you can follow. Please remember to consult your owner’s manual.

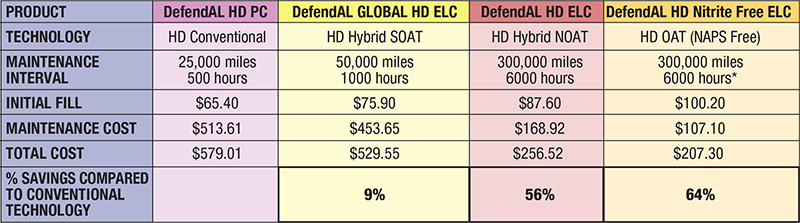

Why not fill with the technology recommended by most OEMs, spend less time on maintenance, AND save over 60% on cost?

Most heavy-duty equipment is now factory-filled with organic acid technology (OAT), nitrite-free antifreeze/coolant. This is typically the most appropriate coolant for modern engines but can appear pricey compared to other coolant technologies. As a result, price-conscious customers are driven to choose conventional technology, even when it isn’t the best technology for the application.

Customers can have the best of both worlds – the best technology for the best price! Because when the cost of heavy-duty nitrite-free technology is the most cost-effective as well. Let’s look at the numbers.

When only the cost of the initial fill is considered, conventional technology is less expensive than nitrite-free. Cost-conscious customers assume that the best deal will be to save $30 at initial fill and buy the conventional product, knowing that it will require more maintenance. However, the picture starts to change when you consider the cost of labor and SCA every 25,000 miles that are required to maintain conventional coolant. Over 1MM miles (the lifetime of DefendAL HD NF), the savings per vehicle adds up to around $370 and the savings for a fleet of 50 vehicles around $18,000!**

*Can typically be maintained through routine top-off, but antifreeze/coolant should be checked every 300,000 Miles/6000 Hours to ensure that it is in proper working order (freeze point, pH, appearance)

**Calculations assume a 15-gallon coolant system, typical for a class 8 engine