Organic Acid Technology is the state-of-the-art technology used as factory fill in most original equipment manufacturers (OEMs), including light and heavy duty makes. This technology may cost more for the initial fill, but maintenance costs are dramatically reduced. Also, this technology is best for protecting the aluminum of modern engines. OAT technology uses organic acid inhibitors such as sebacic acid, benzoic acid, and 2-ethyl hexanoic acid (2-EH) to protect metals in the cooling system from corrosion.

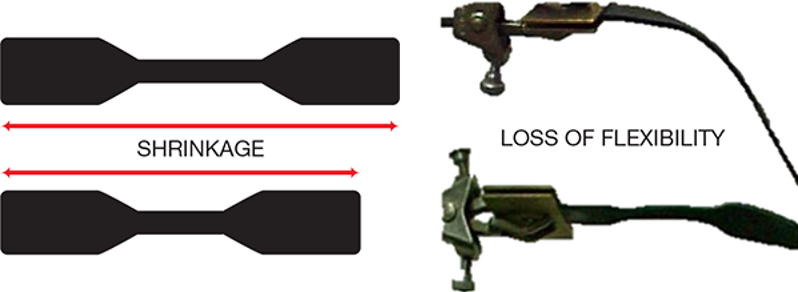

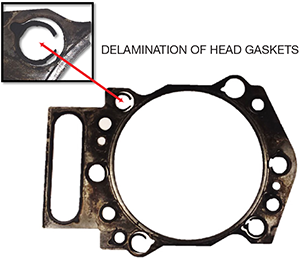

A Word of Caution – It is important to consider OEM recommendations before choosing a coolant, as OEMs know the most about their system and will be knowledgeable about what technology should and shouldn’t be allowed. One example of why this is so important has to do with the presence of 2-EH. While this inhibitor is highly effective in preventing corrosion, it made the General Motors coolant DEX-COOL infamous in the late 90’s/the early ’00s for causing damage to silicon seals,hoses, and gaskets in the cooling system. Ultimately, this cost GM millions of dollars after a settlement of a class-action lawsuit in 20081. The reason the 2-EH caused so many issues is that it was incompatible with the silicon components: it can shrink and dry the elastomer, distorting the shape and causing leaks.

Shrinkage in the elastomeric components in the head gasket can allow exhaust gas to enter the coolant, causing premature degradation of the coolant and corrosion damage.

OEM Recommendations – Light-duty OEMs have mostly moved away from components that can be damaged by 2-EH, and many of the coolants on the American market still contain 2-EH. However, care must be taken when choosing a coolant for a heavy duty application, as some heavy duty OEMs still use silicon seals.For mixed fleets,the best choice is DefendAL Heavy Duty Nitrite-Free Extended Life, as it provides top-of-the-line performance with low maintenance and high compatibility across OEMs.

https://www.reuters.com/article/gm-settlement/gm-settles-lawsuits-over-engine-coolant-problems-idUSN2735011520080327

Maintaining Fluids with SCAs

Frequently at KOST USA, we’re asked about all of the acronym’s used in antifreeze and what they do for engines. So what are SCAs? SCAs are Supplemental Coolant Additives are composed of a concentrated dose of the inorganic inhibitors present in heavy duty conventional and hybrid formulas, typically nitrite and molybdate, that tend to break down in use. Heavy duty conventional and hybrid coolants should have SCA levels checked regularly to ensure that proper levels are maintained.

Light Duty Conventional Coolant + SCA =Heavy Duty Conventional Coolant

Historically, SCAs were used to “charge” light duty conventional formulas, and convert them to heavy duty with the addition of cavitation corrosion inhibitors such as nitrite. Now most users skip the hassle and buy a heavy duty pre-charged coolant, such as DefendAL Heavy Duty Pre-Charged which is ready to use in heavy duty applications.

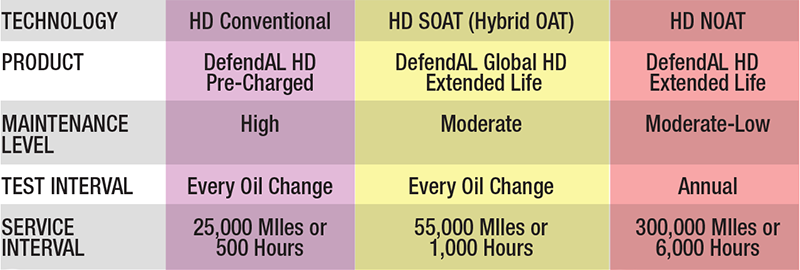

Maintaining fluids containing SCAs is a matter of maintenance. The coolant’s color, clarity, freeze point, pHand SCA levels should be checked at specific test intervals dependent on the coolant technology and then serviced when needed.

Warning – Neglecting to maintain the level of SCAs can result in costly cavitation corrosion to the wet sleeve liners when undertreated. However, more is not always better. Over addition of SCAs can cause inhibitor build-up,water pump damage, and reduced heat transfer.

For field testing, tests strips can be used along with are fractometer to evaluate SCA levels, pH, and freeze point. For more extensive testing, KOST USA’s KOSTCare Program can provide full analysis and recommendations on how to maintain the fluid. This testing is free of charge on an annual basis for KOST USA customers. See chart below for more detailed information on testing intervals.

You could always consider DefenddAL Heavy Duty Nitrite-Free Extended Life Antifreeze/Coolant for a low maintenance option that does not require SCA’s.