A question that come sup frequently is what’s the difference between light and heavy duty antifreeze? KOST USA is here to help answer that. question.

Light duty engines are those in passenger cars or trucks, while heavy duty engines are those in large commercial vehicles like semi trucks, buses,or construction equipment.Both light and heavy duty antifreeze/coolant must protect against a range of challenges that can arise in a cooling system, but the main difference is protection against pitting cavitation: heavy duty formulations contain inhibitors that protect against cavitation while light duty formulations do not.

You should NEVER use light duty coolant in a heavy duty engine, this will cause damage! However, a heavy duty coolant can be generally be used in a light duty cooling system without fear of harm.

Pitting/Cavitation Corrosion – Many heavy duty diesel engines use replaceable liners that fit down around each cylinder to aid in serviceability. A type of liner called a wet sleeve liner fits down around the cylinder and comes into direct contact with the coolant. During an engine rebuild or overhaul, the liner can be replaced to allow the rest of the engine to continue in service.

Cavitation corrosion occurs when vibration from the piston moving in the cylinder causes the wall of the wet sleeve liner to move, resulting in a microscopic reduced-pressure region, or air bubble, on the coolant side of the liner. The air bubble bursts, resulting in an explosion of 15,000 to 20,000 psi1 directed at the wall of the liner. This collapse occurs at a high frequency, and without proper inhibitors can drill holes through the wet sleeve liner,causing catastrophic damage to the engine.

The ONLY way to protect a heavy duty engine from pitting cavitation is to use and maintain coolant with proper heavy duty additives,such as molybdate and nitrite. These inhibitors form a film over the metal protecting it from the effects of cavitation corrosion.

Conventional Versus OAT Technologies

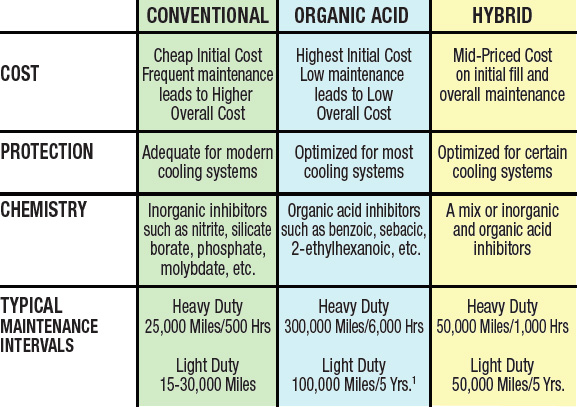

One of the main differences between the types of antifreeze that must be understood is the difference between conventional, organic acid, and hybrid technology coolants.While color may be the most apparent coolant characteristic,the chemical additives within the coolant, called inhibitors, are what provide the protection needed for the cooling system metals. Since these technologies have different maintenance requirements, a failure to understand the type of coolant technology in one’s cooling system could cause damage.

Conventional Technology

The oldest, original coolant technology is called conventional or inorganic technology. This technology is popular with some users because it is familiar and cheap; however maintenance costs can be pricey in the long run, and if a rigorous maintenance schedule is not followed, engine damage can occur.

How it works: Inhibitors react with metallic ions on the surface of the metal to form and continuously repair an insoluble protective film throughout the system2, thus protecting the metal against corrosion. However, the inhibitors are used up when they rebuild the film, which results in a need to maintain the coolant more frequently1.

Organic Acid Technology (OAT)

Organic Acid Technology is the technology used as factory fill in most American original equipment manufacturers (OEMs),including light and heavy duty makes. This technology may cost more for the initial fill, but maintenance costs are dramatically reduced. Also, this technology is the best coolant for protecting the aluminum of modern engines. Heavy duty variants will contain nitrite and or molybdate for cavitation corrosion protection. However, many heavy duty OEMs are moving to a nitrite-free version because the increased heat that the coolant has to withstand in modern heavy duty engines can cause rapid consumption of nitrite.

How it works: Organic acids are triggered by pH changes in the corrosive process to move to trouble spots in the system and create a hydrophobic precipitate layer2 to protect from corrosion. Once the natural protective oxide layer of the aluminum is restored, inhibitors can be returned to their original form and are reused1.

Hybrid Technology

Hybrid technology is a mixture of conventional and organic acid technologies, with the inorganic inhibitors added for extra protection of known cooling system weaknesses. NOAT, POAT,SOAT coolants are all examples of hybrids, respectively referring to nitrited organic acid technology, phosphated organic acid technology, and silicated organic acid technology. Some OEMs recommend the use of specific hybrids in their cooling systems while forbidding the use of others. This has led to the proliferation of many different hybrid types, each specifically designed for particular OEMs. When a coolant is needed to suit multiple OEMs, typically a full OAT coolant is recommended, as this satisfies the performance requirements of most OEMs.